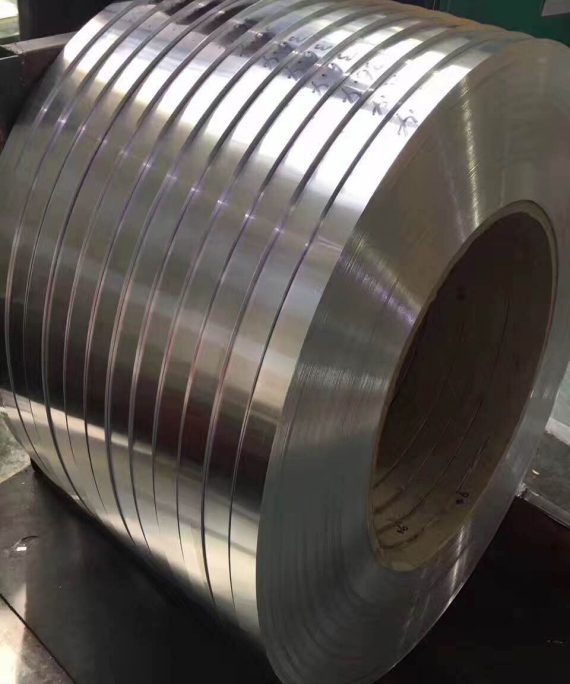

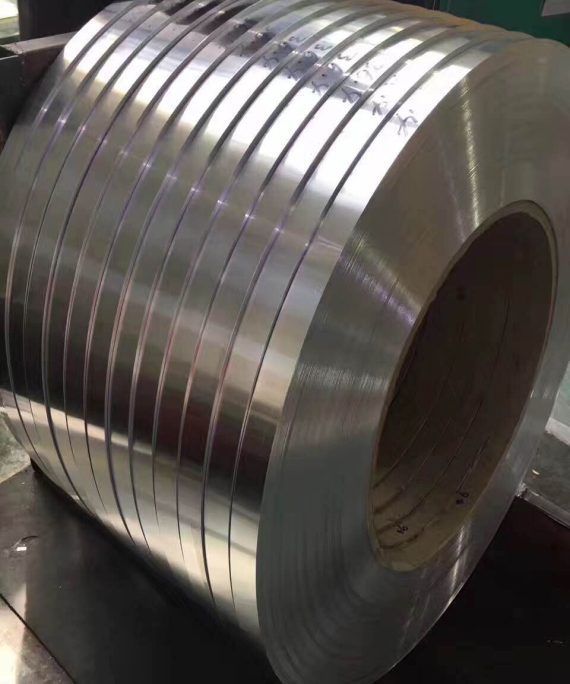

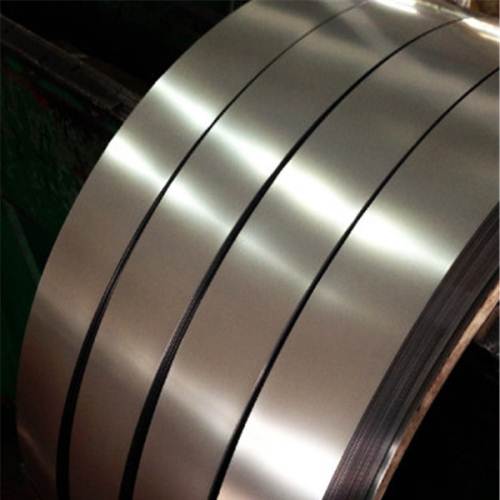

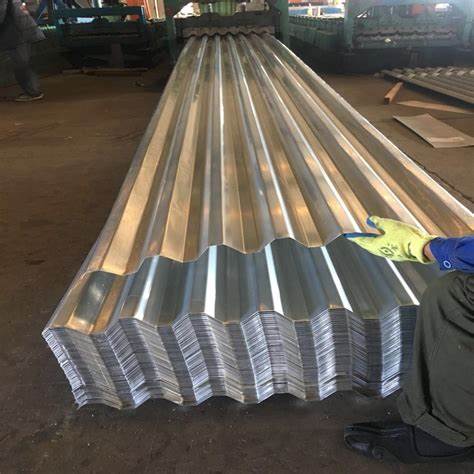

GALVANIZED STEEL

Galvanized steel is among the most popular steel types because of its extended durability, having the strength and formability of steel plus the corrosion protection of the zinc-iron coating. The zinc protects the base metal by acting as a barrier to corrosive elements, and the sacrificial nature of the coating results in a long-lasting and high-quality steel product.

This versatility makes it applicable to a variety of projects and industries, including agriculture, solar, automotive, construction, and so on. Below, we aim to provide a comprehensive description of how galvanized steel is processed, different galvanization methods, its benefits, and how it is used in these various industries.

If the varieties, specifications and special requirements of products are not covered in the manual, please feel free to contact us. Chenxin steel will reply you as soon as possible.

Grade and appliances

| Steel Grade | Code Of Zinc

Coating Weight |

Executive Standard | Main Application |

| DX51D+Z ( STO2Z ) | NORMAL | ||

| DX52D+Z ( STO3Z ) | DRAWING | ||

| DX53D+Z ( STO4Z ) | Z60-Z350 | Q/ASB 385 | DEEP DRAWING |

| S220GD+Z. S250GD+Z

S280GD+Z. S320GD+Z S350GD+Z、S550GD+Z |

CONSTRUCTION | ||

| SGCC | NORMAL | ||

| SGCD1 | DRAWING | ||

| SGCD2、 SGCD3 | Z60-Z350 | Q/ASB 387 | DEEP DRAWING |

| SGC34, SGC400S SGC440、 SGC490, SGC570 | CONSTRUCTION | ||

| CSA、CSB、CSC | NORMAL | ||

| FS A、FS B | Z60-Z350

( METRIC SYSTEM ) G20-G115 (ENGLISH SYSTEM ) |

DRAWING | |

| DDSA、DDSC | Q/ASB 10 | DEEP DRAWING | |

| SS33(230)、SS37(255)、SS40(275) SS50(340)、SS80(550) | CONSTRUCTION |

STANDARD AND PROPERTIES -DRAWING STEEL

Variety, surface structure and after-treatment mode of zinc coating

| Item | Type |

| Variety Of Zinc Coating | Pure Zinc |

|

Surface Structure |

Normal Spangle |

| No Spangle | |

| Skin-Passed Spangle | |

|

After-Treatment Mode |

Normal Passivation |

| Environmental Passivation | |

| Fingerprint Resistance | |

| Oiling | |

| Passivating And Oiling | |

|

Surface Quality Level |

Normal Level |

| High Level | |

| Higher Level |

Steel grade and chemical composition Q/ASB 385

| Steel grade | Chemical composition%, no greater than | |||||

| C | Si | Mn | P | S | Ti | |

| DX51D+Z ( STO2Z )

DX52D+Z ( STO3Z ) DX53D+Z ( STO4Z ) |

0.12 | 0.50 | 0.60 | 0.10 | 0.03 | 0.3 |

| S220GD+Z,S250GD+Z

S280GD+Z,S320GD+Z S350GD+Z,S550GD+Z |

0.20 | 0.60 | 1.70 | 0.10 | 0.035 | – |

|

Steel grade |

Chemical composition%, no greater than | |||

| C | Mn | P | S | |

| SGCC | 0.15 | 0.80 | 0.05 | 0.030 |

| SGCD 1 | 0.12 | 0.60 | 0.04 | 0.030 |

| SGCD2 | 0.10 | 0.45 | 0.03 | 0.030 |

| SGCD 3 | 0.08 | 0.45 | 0.03 | 0.030 |

| SGC340 | 0.25 | 1.70 | 0.20 | 0.035 |

| SGC400 | 0.25 | 1.70 | 0.20 | 0.035 |

| SGC440 | 0.25 | 2.00 | 0.20 | 0.035 |

| SGC490 | 0.30 | 2.00 | 0.20 | 0.035 |

| SGC570 | 0.30 | 2.50 | 0.20 | 0.035 |

Steel grade and chemical composition Q/ASB 387

Mechanical properties and processing properties of sheet and strip Q/ASB385

| Steel grade | Tensile test | ||

| Lower yield strength

MPa |

Tensile strength

Rm MPa |

Breaking elongation% (Lo=80mm,b=20mm ) | |

| Not less than | |||

| DX51D+Z(StO2Z) | – | 270-550 | 22 |

| DX52D+Z ( StO3Z ) | 140-300 | 270-420 | 26 |

| DX53D+Z ( StO4Z ) | 120-260 | 270-380 | 30 |

| S220GD+Z | 5=220 | N300 | 20 |

| S250GD+Z | 5=250 | 5=330 | 19 |

| S280GD+Z | N280 | 5=360 | 18 |

| S320GD+Z | N320 | 5=390 | 17 |

| S350GD+Z | 5=350 | >420 | 16 |

| S550GD+Z | >550 | N560 | 一 |

Mechanical properties and processing properties of sheet and strip Q/ASB 387

| Steel grade | Tensile test | ||

| Lower yield strength bK .MPa | Tensile strength

Rm ,MPa |

Breaking elongation (L(,=50mm,b=20mm ) | |

| Not less than | |||

| SGCC | 205 | 270 | |

| SGCD1 | – | 270 | 38 |

| SGCD2 | – | 270 | 40 |

| SGCD3 | – | 270 | 42 |

| SGC340 | 245 | 340 | 20 |

| SGC400 | 295 | 400 | 18 |

| SGC440 | 335 | 440 | 18 |

| SGC490 | 365 | 490 | 16 |

| SGC570 | 560 | 570 | – |

Equivalent thickness of zinc coating (the sum thickness of two sides)

| Code of zinc coating | Z80 | Z90 | Z100 | Z120 | Z140 | Z150 | Z160 |

| Equivalent thickness of zinc coating mm | 0.011 | 0.013 | 0.014 | 0.017 | 0.02 | 0.021 | 0.022 |

| Code of zinc coating | Z180 | Z200 | Z220 | Z225 | Z250 | Z270 | Z275 |

| Equivalent thickness of zinc coating mm | 0.025 | 0.028 | 0.031 | 0.031 | 0.035 | 0.039 | 0.039 |

Reviews

There are no reviews yet.