What are the different types of steel plates used for construction?

- Checkered Plates

- Galvanized Plates

- Mid Steel Plates

- B.I. and G.I. Plates

Steel plate is the term used for any steel material that is formed into a plate. It is one of the most versatile metal materials as it is available in various widths, lengths and finishes. Steel plate can also be further processed into different shapes. Depending on how these steel plates are processed, they can be used for diverse and complex construction applications – mainly for structural supports and profiles.

There are many types of steel plate used in construction. Each steel plate has its own set of properties, ranging from corrosion resistance to the ability to withstand different temperatures. Steel plates in the construction of bridges, railways, warehouses and buildings. Because every construction project is unique, choosing the right steel plate specification is crucial.

Read on to find out more about the different types of steel plate used in construction.

Checkered plates

Checkered plates are characterised by raised angular patterns on the surface of the plate. These raised patterns provide more grip over the entire surface of the plate. This makes it easier to move around during use.

Due to the texture of the checkered steel plates, people experience less slipping and sliding. That’s why it’s the ideal material for walkways and paths for both people and vehicles. You can see this steel plate in car park floors, lift floors and industrial stairs. Its texture makes it safer and more secure to walk on.

Aside from flooring, you can find this steel plate used as corner guards for walls and door kick plates.

Checkered plates are also easy to maintain. Their surfaces are resistant to many unwanted elements such as dirt, oils, dust and various liquids.

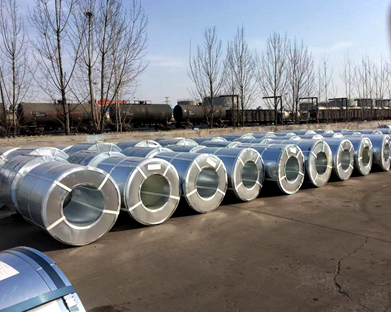

Galvanized Plates

Galvanised steel sheet is characterised by its strength and resistance to corrosion. Galvanisation involves dipping the steel into molten zinc to add an extra layer of strength. Despite its strength, galvanised sheet can be formed into a variety of shapes. This makes it ideal for many projects.

Galvanised sheet also has a higher resistance to wear and tear due to the extra layer of zinc. This means that they can withstand a wide range of temperatures. That’s why it’s used in various household appliances such as water heaters.

It is also a common choice for sheds and roofing, such as corrugated sheets. It is also used in cars because of its durability and long life. You can expect galvanised steel sheet to last a few decades as it takes a while for the anti-corrosion treatment to wear off.

Mild Steel Plates

Mild steel plate is the most popular plate in the construction industry because of its versatility and ease of use. It is a type of carbon steel and is available in various thicknesses.

These plates can be easily welded or formed into different shapes. This makes it useful when construction companies are building structures and sections. It can also be cut and bent into different shapes, making it easy to form different steel structures and equipment.

What’s more, mild steel doesn’t require special tools to cut or remove sections of the plate.

You’ll see mild steel used for many construction and industrial purposes. It can also be used in the marine industry to make offshore equipment. It is also used in the construction of various infrastructure such as warehouses, buildings, bridges and transport terminals.

B.I. and G.I. Plates

Black Iron (B.I.) and Galvanised Iron (G.I.) sheets are two common steel sheets used in construction. G.I. sheets are characterised by their protective metallic coating to prevent corrosion. On the other hand, B.I. sheets are made with copper and aluminium.

Both steel sheets are coated with zinc on all sides, as in the galvanising process. In addition, electro-galvanising is also used. This is an electric current that is passed through the sheet after the zinc has been applied. This gives it greater resistance and strength against the various elements.

Application of G.I. Steel Plates

- Household appliances. Durable yet lightweight, it is a good material for many household appliances.

- Doors and wall panels. Its flat surfaces are ideal for creating the panels needed for both commercial and residential buildings.

- Roofing. Zinc’s protective coating makes it ideal for roofing, as it is resistant to various elements.

Application of B.I. Steel Plates

- Billboards. The appearance of B.I. sheets makes them an ideal choice for outdoor advertising.

- Air conditioning systems. Its corrosion resistance and light weight make it perfect for cooling systems.

- Automotive. Its strength and thickness make it a good material for cars.

Key Takeaway

There are many types of steel plate used in construction because it is a common material used in industry. These different plates allow companies to make different types of parts and equipment. Now you’ll be able to identify which type of plate is best for your upcoming construction projects.

If you’re looking for high quality yet affordable steel plates in China, you can contact us here at Metal Exponents. We are the best steel manufacturer and steel supplier in China!